Leminar has revolutionized the ducting industry by introducing GI ductwork which is produced on a fully automated duct line with CGF 1 integral flange system. The flanges are produced from the same sheet and forms an integral part of the duct itself. The longitudinal seam for the straight duct is closed on same coil line which gives an excellent quality of lockseam joint.

SALIENT FEATURES OF CGF1 INTEGRAL FLANGE SYSTEM

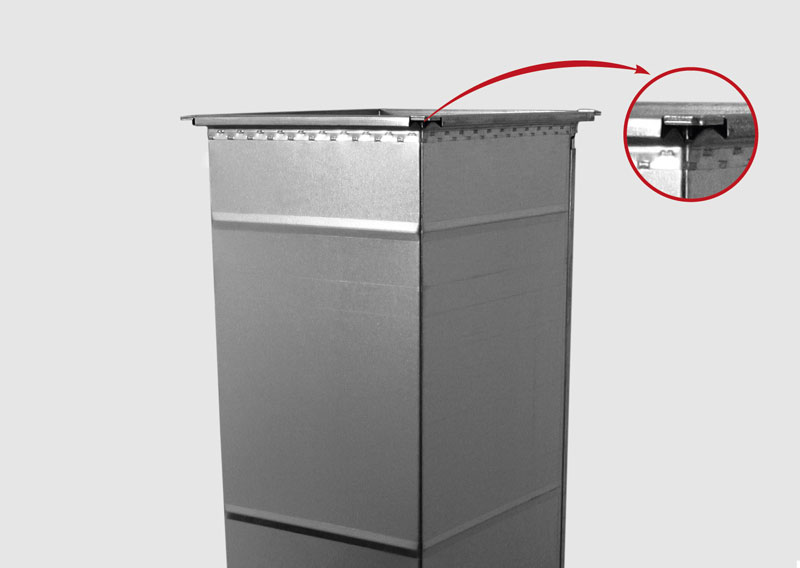

CONSTRUCTION :-

Duct manufactured in two Profile sizes. | 20 mm Profile (J2 Rating) | 30 mm Profile (J3 to J6 Rating)

THIRD PARTY CERTIFICATION – BSRIA

Ducts are tested, certified and approved as per DW/TM1 scheme of rectangular cross flow / transverse joints of the Ductwork standard DW144 in all parameters by BSRIA-UK. The ducts are having valid BSRIA certification for different

CGF1 20 & 30 flange joint ratings.

SMACNA/DW-144

Meets SMACNA and DW-144 standards. The Duct flange with highest rating CGF1 30 mm achieves J6 rating as per

SMACNA & DW-144 which is highest in the industry.

BENEFITS OF CGF1 INTEGRAL FLANGE SYSTEM

LOW LEAKAGE RATING RESULTING IN INCREASED ENERGY EFFICIENCY:

As CGF 1 system is an integral flange type joining system, it has a very low leakage rating. Reduced leakage will provide energy savings to the client (end user) , better equipment efficiency and Indoor Air Quality ( IAQ ). (Other conventional Slip on flange type joining system will have leakages which will reduce the efficiency of the system).

SEALANT APPLICATION:

The CGF1 flanges are integrally formed from the same sheet as that of the ducts hence the use of sealant is not required along the transverse joints. This is applicable for low, medium and high pressure systems. (Other conventional Slip on flange type joining system will require a sealant to be applied).

ENVIRO FRIENDLY / NO RIVETS TO FIX TRANSVERSE FLANGES :

The CGF 1 Flange system does not require any rivets for fixing the flanges which gives an unobstructed airflow. Also, as the internal surface is smooth hence there is less accumulation of dust (Other conventional Slip on flange type joining system will require rivets to be used for fixing flanges which will puncture the duct and cause leakages, the dust will get accumulated around the rivets after certain period resulting in bacterial growth).

STRENGTH

The inherent strength of the CGF1 integral flange (30 mm) enables it to be used for ducts upto 3000 mm size. It complies to Low, Medium and High pressure ducts with minimal joint deflection. Double hollow profile provides good strength to the duct system. (Other conventional Slip on flange type of the same size (30 mm) cannot be used for large ducts of this size).

LOAD ON STRUCTURE:

The 30 mm CGF 1 flanges are J6 rated (as per classification of transverse joints in DW-144 standard) which is equivalent to a conventional 50 mm x 50 mm x 5 mm size rolled steel angle ( RSA) flange. Hence, these flanges are lighter and will have less weight on the structure, at the same time complying with higher ratings of transverse joints. (Other systems use heavy slip on flanges and rolled steel angles for bigger ducts which causes extra load on the structure).

FAST PRODUCTION:

The Ducts produced on CGF-1 fully automated machine will have high productivity. This will ensure more deliveries to project site on less turn around production time and will help in scheduled execution of projects. (Other conventional slipon flange system involves multiple handling operations on different machines ( such as Auto fold machine, Seam Closure machine, Flange fixing operation, Riveting operation etc).